In modern construction, thermal performance is no longer optional — it’s mandatory. Whether you’re designing an industrial skylight, commercial facade, warehouse roofing, or railway canopy, understanding U-Value and SHGC is critical.

If you’re using polycarbonate sheets, this guide will help you understand:

What is U-Value?

What is SHGC?

How they impact heat, energy efficiency & comfort

Polycarbonate vs Glass comparison

Which thickness performs better

What to choose for Indian climate (especially hot regions)

Let’s simplify it.

What is U-Value in Polycarbonate Sheets?

U-Value (Thermal Transmittance) measures how much heat passes through a material.

Lower U-Value = Better insulation

Higher U-Value = More heat transfer

It is measured in:

W/m²K (Watts per square meter per Kelvin)

Why U-Value Matters in Roofing & Facades

In India, especially in hot climates like Delhi NCR, Rajasthan, Gujarat:

High U-Value → More heat enters building

AC load increases

Electricity bills rise

Indoor discomfort increases

That’s why architects search for:

“low U value roofing sheet”

“thermal insulation polycarbonate sheet”

“energy efficient skylight material”

Typical U-Values of Polycarbonate Sheets

| Thickness | Type | Approx U-Value |

|---|---|---|

| 6mm Solid | Solid | 5.5 – 5.8 W/m²K |

| 10mm Multiwall | Multiwall | 2.8 – 3.0 W/m²K |

| 16mm Multicell | Multicell | 2.1 – 2.5 W/m²K |

| 25mm Multicell | Multicell | 1.5 – 1.8 W/m²K |

More chambers = Better insulation

Thicker sheet = Lower U-Value

What is SHGC in Polycarbonate Sheets?

SHGC (Solar Heat Gain Coefficient) measures how much solar radiation passes through the material.

It is expressed as a value between 0 and 1.

Lower SHGC = Less solar heat enters

Higher SHGC = More heat enters

Why SHGC is Important?

In tropical countries like India:

High SHGC → More solar heat → Hot interiors

Low SHGC → Reduced heat gain → Energy savings

Typical SHGC Values

| Sheet Type | SHGC Range |

|---|---|

| Clear Solid PC | 0.80 – 0.90 |

| Opal / Diffused PC | 0.40 – 0.60 |

| IR Cut Polycarbonate | 0.25 – 0.45 |

IR coated or opal sheets reduce solar heat significantly

Ideal for industrial roofing & factories

Polycarbonate vs Glass (Thermal Comparison)

| Property | Polycarbonate (16mm Multicell) | 6mm Glass |

|---|---|---|

| U-Value | ~2.2 W/m²K | ~5.8 W/m²K |

| SHGC | 0.40 – 0.60 | 0.75 – 0.85 |

| Impact Resistance | 200x Stronger | Fragile |

| Weight | Lightweight | Heavy |

Polycarbonate provides better insulation

- Lower AC load

- Higher impact resistance

- Better daylight diffusion

Where Low U-Value & SHGC Matter Most

Industrial skylights

Warehouse roofing

Railway platforms

Airport canopies

Shopping malls

Car parking sheds

Hospital corridors

Educational institutions

If your project is targeting:

LEED Certification

ECBC Compliance

Energy Efficient Building Design

Then U-Value & SHGC are mandatory considerations.

Which Polycarbonate Thickness Should You Choose?

For Car Parking

10mm or 16mm Multicell

For Industrial Roofing

16mm or 25mm Multicell

For Skylight with Daylight Diffusion

Opal 16mm Multicell

Why Choose Coxwell Polycarbonate Sheets?

When it comes to performance, not all sheets are equal.

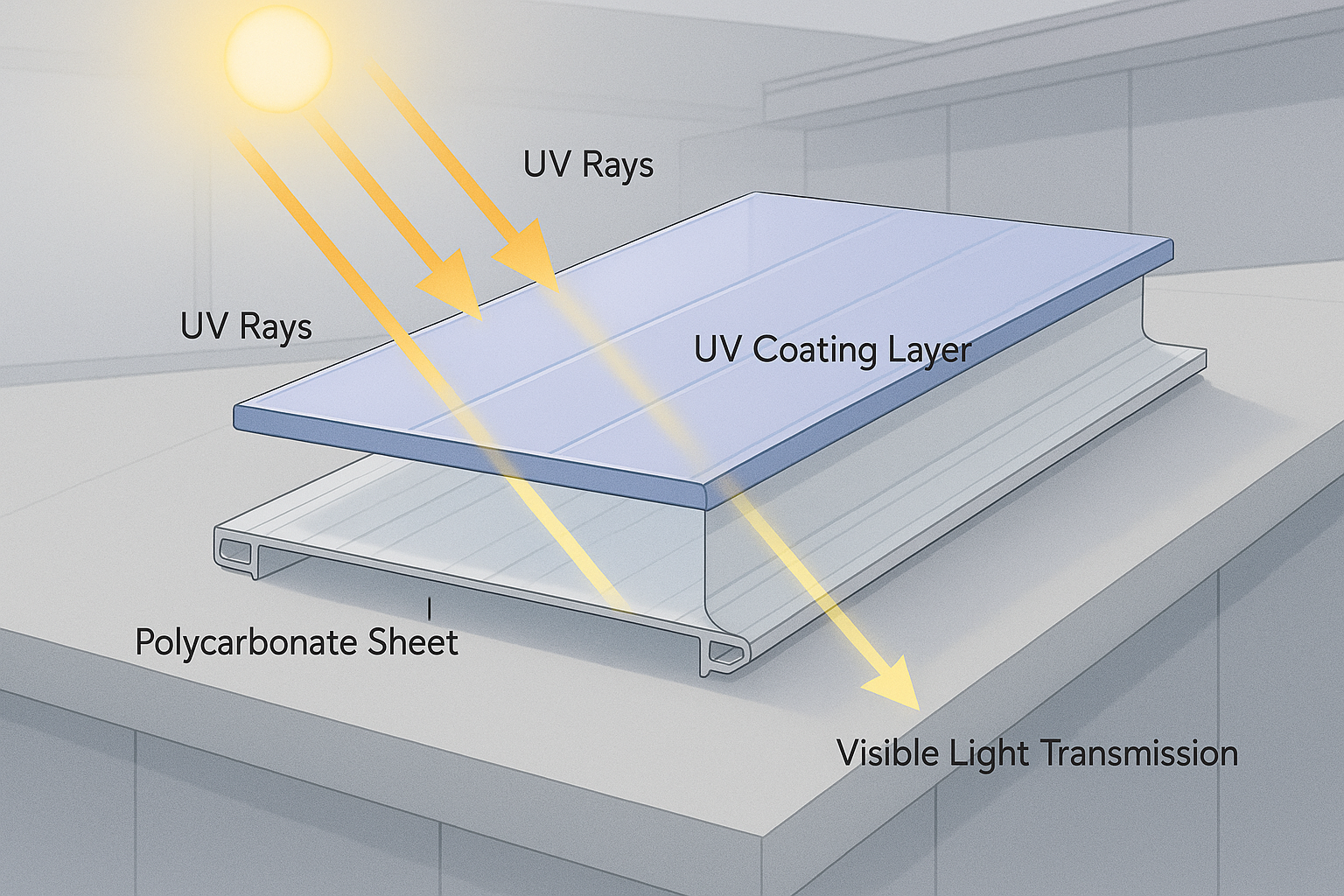

Coxwell Polycarbonate Sheets offer:

- Optimized low U-Value Multicell sheets

- Advanced IR Cut technology for lower SHGC

- UV protected sheets (co-extruded layer)

- High impact resistance

- Long service life

- Suitable for industrial & government projects

Get Technical Specifications Today

If you’re:

An architect designing skylights

A contractor working on industrial roofing

A consultant evaluating thermal performance

A government project authority

Contact Coxwell today to get:

Complete Technical Data Sheet (TDS)

U-Value & SHGC certified reports

Thickness recommendation for your project