Introduction

In architectural daylighting systems, material longevity and optical performance are as critical as structural strength. Polycarbonate sheets are widely specified for skylights, canopies, pergolas, and façades due to their impact resistance and lightweight nature. However, their long-term performance in outdoor applications depends heavily on UV coating technology.

This article explains, from a technical perspective, how UV coating works in polycarbonate sheets, why it is essential for exterior use, and what architects should evaluate while specifying UV-protected systems.

Understanding UV Radiation and Polymer Degradation

Ultraviolet radiation (200–400 nm wavelength) initiates photo-oxidative degradation in thermoplastic polymers. In polycarbonate sheets, prolonged UV exposure can result in:

- Chain scission of polymer molecules

- Reduction in tensile and impact strength

- Yellowing and haze formation

- Surface embrittlement and micro-cracking

Without protection, these effects significantly reduce service life and optical clarity, making UV protection mandatory for architectural-grade polycarbonate sheets.

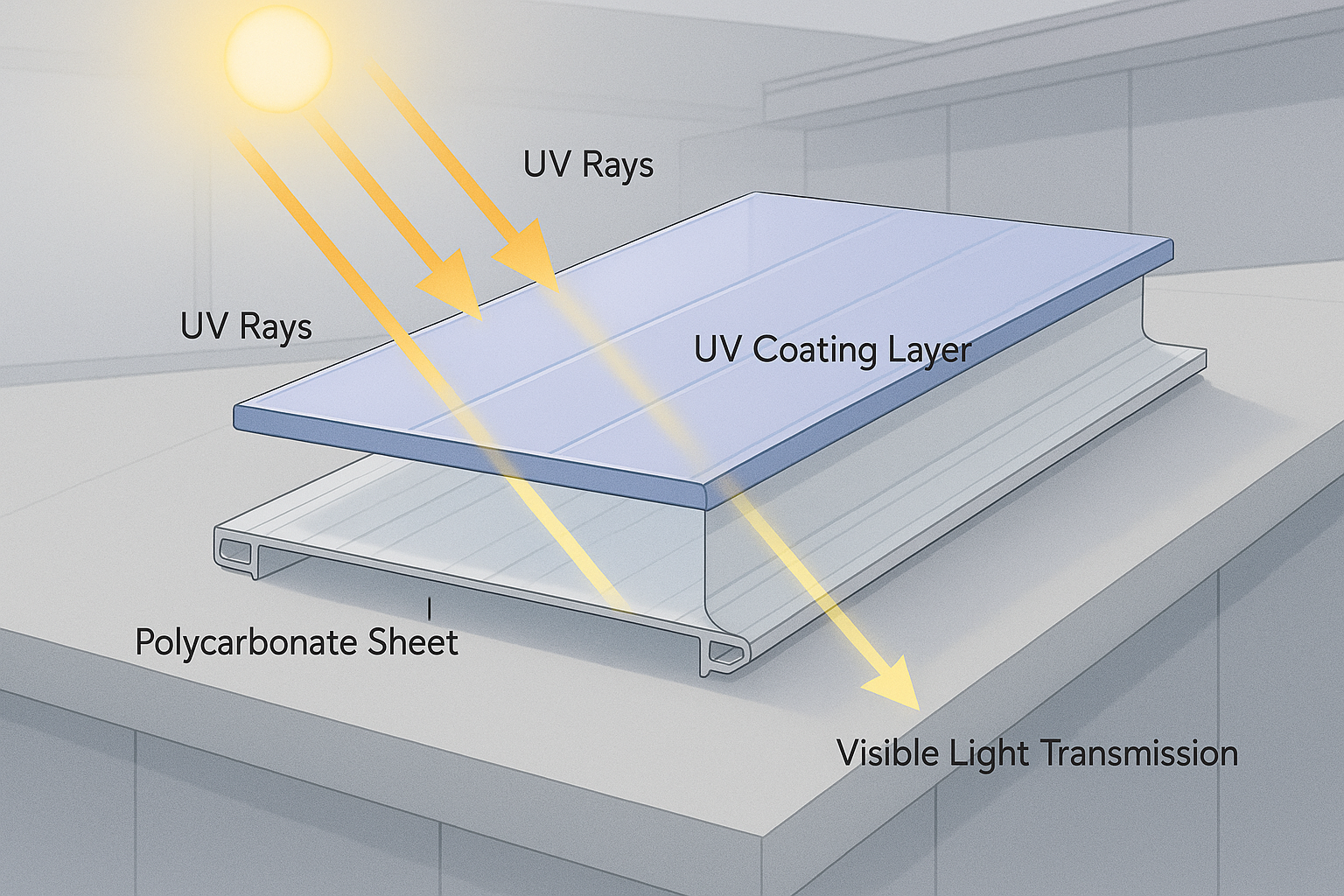

What Is UV Coating in Polycarbonate Sheets?

UV coating is a thin, engineered protective layer applied to polycarbonate sheets during extrusion. Its function is to absorb, filter, and block harmful ultraviolet radiation before it penetrates the substrate.

Unlike bulk UV stabilizers, UV coating forms a dedicated functional barrier that directly interacts with solar radiation at the exposed surface.

How UV Coating Works: Technical Mechanism

1. UV Absorption at the Surface

UV coating contains specialized UV-absorbing compounds that intercept ultraviolet photons. These molecules absorb high-energy UV radiation and dissipate it as low-energy heat, preventing transmission into the polycarbonate sheet.

2. Protection of Polymer Chains

By stopping UV radiation at the surface, the coating prevents photo-degradation of carbonate linkages within the polymer. This preserves:

- Mechanical integrity

- Impact resistance

- Flexural strength

- Optical clarity

3. Selective Light Transmission

High-quality UV coating blocks harmful UV wavelengths while allowing high visible light transmission (VLT), which is critical for daylighting performance.

Co-Extrusion Technology: The Industry Standard

Architectural-grade polycarbonate sheets use co-extruded UV coating, not post-applied sprays.

Co-Extrusion Process:

- UV layer and base polycarbonate are extruded simultaneously

- The UV coating becomes molecularly bonded to the sheet

- Coating thickness is precisely controlled

- Long-term adhesion is ensured

This method ensures uniform UV protection across the entire sheet lifespan, unlike surface coatings that may erode over time.

Single-Side vs Double-Side UV Coating

Single-Side UV Coating

- Applied on one surface only

- Requires correct installation orientation

- Suitable for skylights, pergolas, and roofing

Double-Side UV Coating

- UV protection on both surfaces

- Recommended for façades, vertical glazing, and reflective environments

- Reduces risk of incorrect installation

Architects should always confirm UV-protected side marking during specification.

UV Coating vs UV-Stabilized Polycarbonate Sheets

This distinction is critical during material selection:

Feature | UV Stabilized | UV Coated |

Protection method | Additives mixed in resin | Dedicated surface layer |

UV blocking efficiency | Moderate | High |

Long-term clarity | Limited | Excellent |

Outdoor lifespan | Shorter | Significantly longer |

For exterior architectural applications, UV-coated polycarbonate sheets are strongly recommended over merely UV-stabilized alternatives.

Performance Benefits for Architectural Applications

Specifying UV-coated polycarbonate sheets provides:

- Extended service life (10–15+ years depending on exposure)

- Reduced yellowing and haze

- Stable light transmission values

- Lower maintenance and replacement costs

- Improved occupant comfort by reducing UV penetration

These benefits directly impact life-cycle cost analysis and building envelope performance.

Standards and Performance Considerations

While UV coating performance is manufacturer-specific, architects should look for compliance or testing related to:

- Light transmission (ASTM D1003)

- Weathering resistance (QUV / accelerated aging tests)

- Manufacturer UV warranty (clarity and structural retention)

Request technical datasheets and warranty documentation during specification.

Key Applications Requiring UV-Coated Polycarbonate Sheets

UV coating is essential in:

- Skylights and roof glazing

- Pergola and patio roofing systems

- Walkway canopies

- Industrial and commercial daylight roofing

- Façades and vertical daylight panels

- Greenhouse and semi-conditioned spaces

Any polycarbonate sheet exposed to direct or reflected sunlight must include UV protection.

Specification Best Practices for Architects

When specifying polycarbonate sheets, clearly define:

- UV coating type (single or double side)

- Orientation requirements

- Expected service life

- Warranty terms against yellowing and loss of strength

- Compliance with relevant test standards

Avoid generic terms like “UV protected” without technical clarification.

Conclusion

The performance of polycarbonate sheets in architectural applications is fundamentally dependent on UV coating technology. UV coating acts as a critical protective barrier that preserves optical clarity, mechanical strength, and long-term reliability under solar exposure.

For architects and façade consultants, understanding how UV coating works ensures better material specification, improved building performance, and reduced lifecycle risks.

In daylight-driven design, UV coating is not an add-on — it is a necessity.