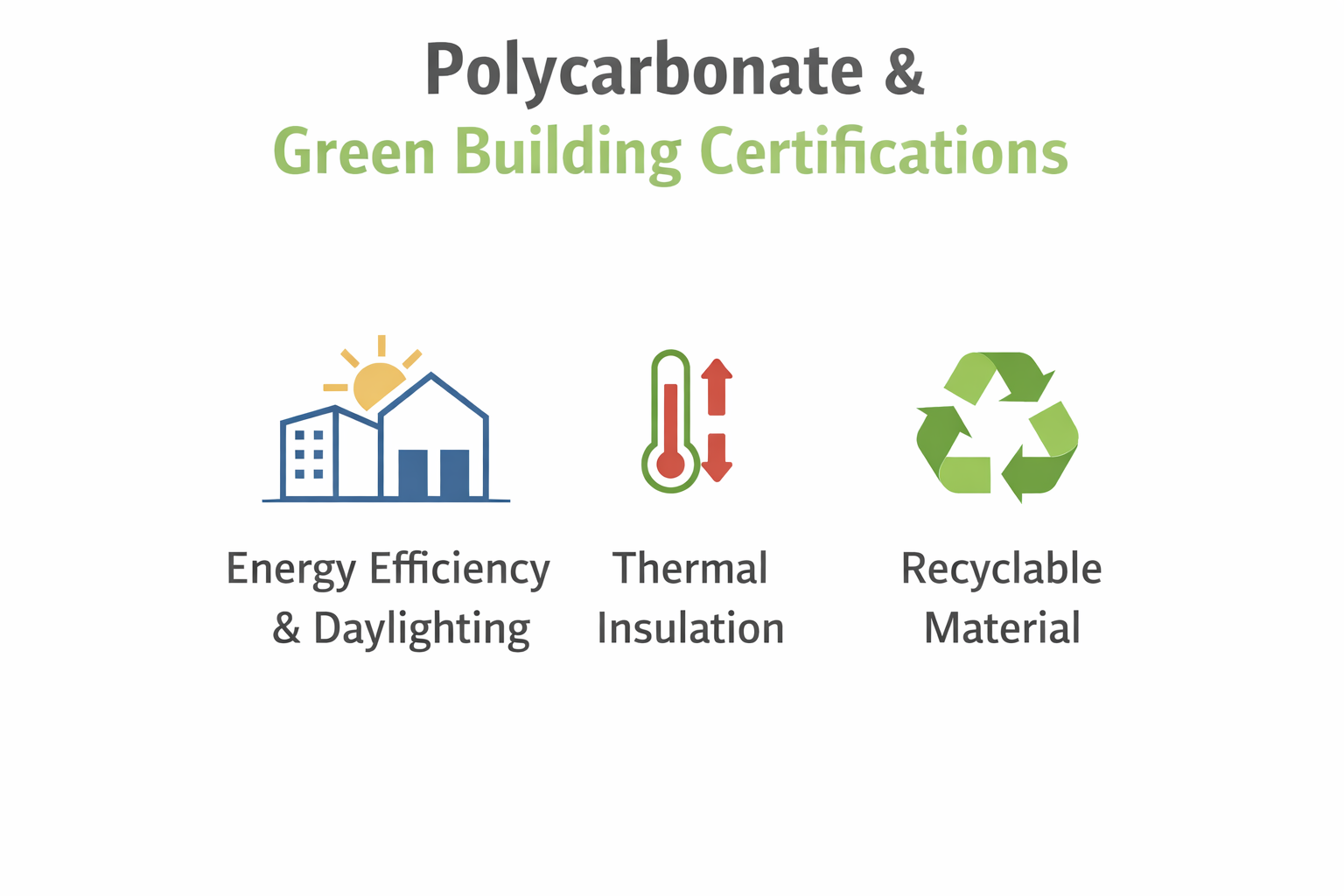

As sustainability becomes a core requirement rather than a design trend, green building certifications like LEED and GRIHA are playing a decisive role in how buildings are planned, designed, and constructed. Architects and developers today are actively seeking materials that improve energy efficiency, daylight performance, thermal comfort, and environmental impact—all while remaining cost-effective and durable.

This is where polycarbonate sheets emerge as a smart, future-ready building material. From façades and skylights to roofing and partitions, polycarbonate significantly contributes toward achieving green building certifications when used correctly.

Understanding Green Building Certifications: LEED & GRIHA

Before diving into material performance, it’s important to understand what LEED and GRIHA evaluate.

LEED (Leadership in Energy and Environmental Design)

Developed by the U.S. Green Building Council, LEED focuses on:

Energy efficiency

Indoor environmental quality

Sustainable materials

Innovation in design

Reduced carbon footprint

GRIHA (Green Rating for Integrated Habitat Assessment)

India’s national green building rating system, supported by TERI, evaluates:

Climate-responsive design

Energy and water optimization

Sustainable building materials

Waste reduction

Occupant comfort

Both certifications reward projects that integrate high-performance envelope materials—a category where polycarbonate sheets excel.

Why Polycarbonate Sheets Are Ideal for Green Buildings

1. Daylighting & Reduced Artificial Lighting

One of the biggest contributors to LEED and GRIHA points is effective daylighting.

Polycarbonate sheets:

Transmit up to 80% natural daylight

Diffuse light evenly, reducing glare

Lower dependency on artificial lighting during daytime

This directly supports:

LEED Daylight Credit

GRIHA Visual Comfort & Energy Optimization criteria

Natural daylight not only saves energy but also improves occupant productivity and wellbeing.

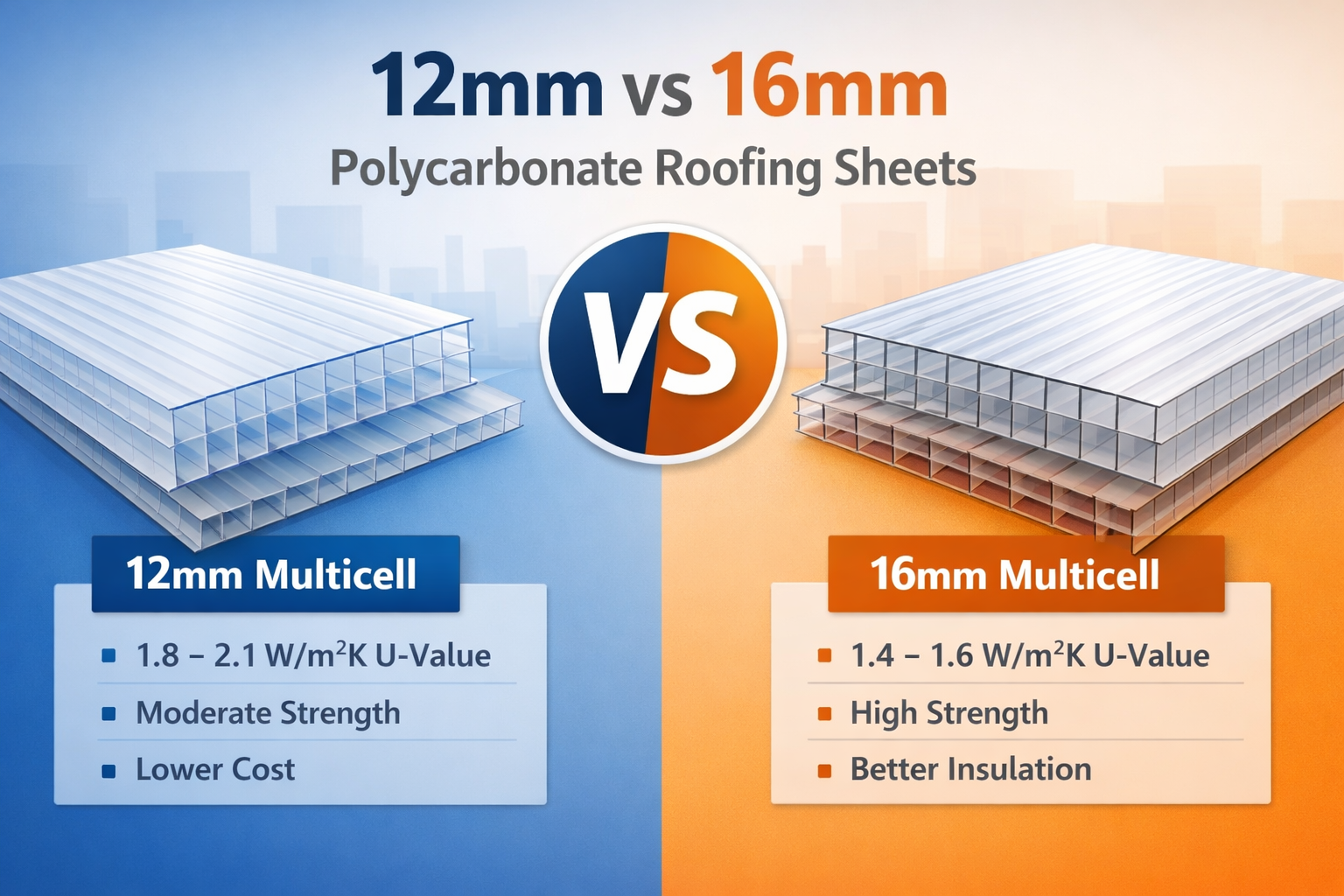

2. Superior Thermal Insulation & Energy Efficiency

Multiwall and multicell polycarbonate sheets trap air within their structure, creating excellent thermal insulation.

Benefits include:

Reduced heat gain in summer

Lower heat loss in winter

Decreased HVAC energy consumption

This improves:

Building envelope performance

Annual energy savings

Compliance with energy efficiency benchmarks under both LEED and GRIHA

3. Lightweight, Low-Carbon Construction Material

Compared to glass and conventional façade materials, polycarbonate sheets are:

Extremely lightweight

Easier to transport and install

Structurally efficient with less supporting steel

This results in:

Reduced embodied carbon

Lower construction energy

Better material efficiency scores under green building certifications

4. Recyclability & Sustainable Material Credits

Polycarbonate is a fully recyclable thermoplastic, aligning with circular economy principles.

Green certification advantages:

Supports LEED Materials & Resources credits

Meets GRIHA sustainable material selection guidelines

Reduces construction and demolition waste

Using recyclable polycarbonate sheets strengthens a project’s sustainability narrative and certification score.

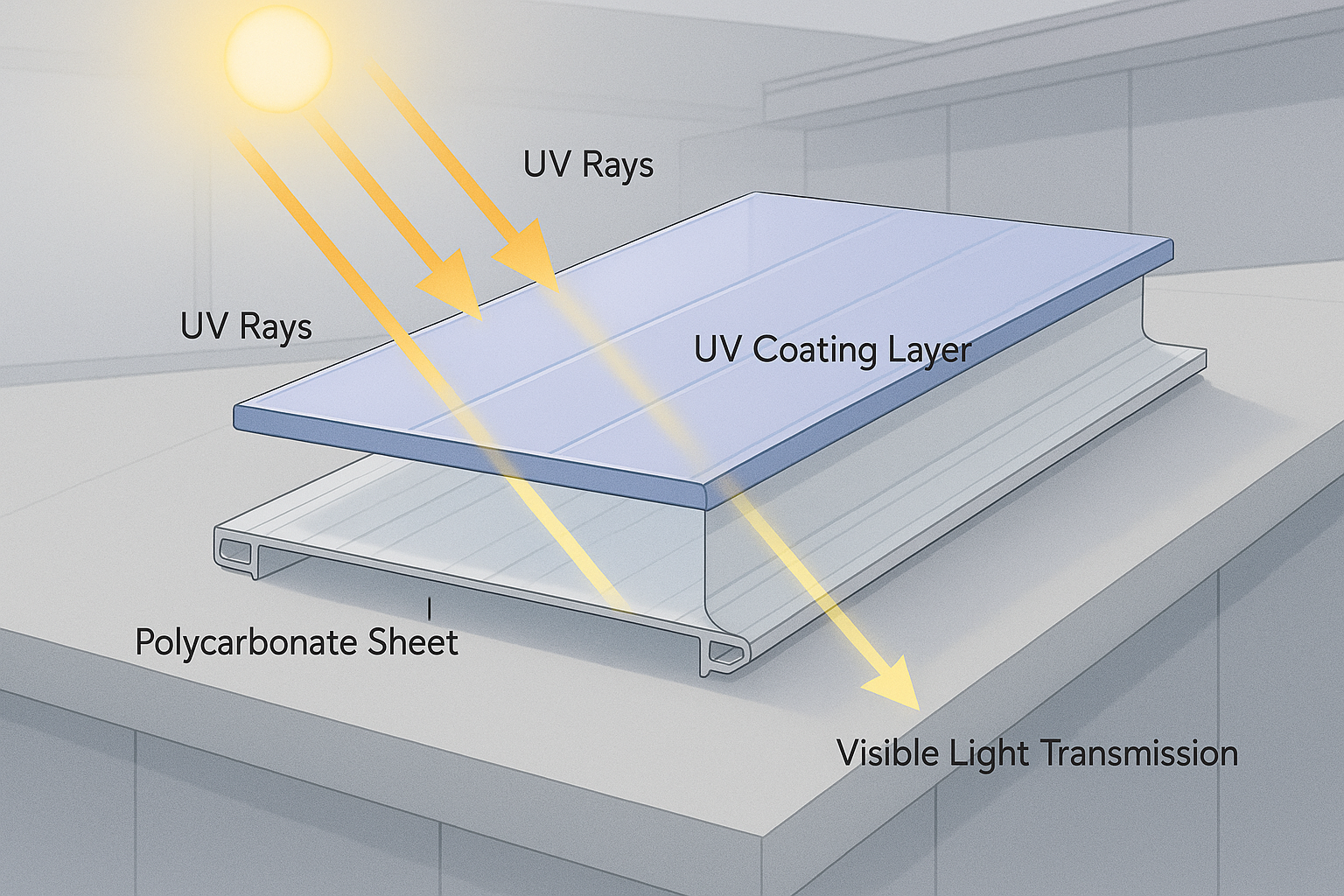

5. Durability, Long Life & Reduced Maintenance

Durability is often overlooked—but it plays a key role in sustainability.

Polycarbonate sheets offer:

High impact resistance

UV protection against yellowing

Long service life with minimal maintenance

Longer material life means:

Fewer replacements

Lower lifecycle environmental impact

Improved building performance over decades

6. Design Flexibility Without Performance Compromise

Green buildings don’t need to sacrifice aesthetics.

Polycarbonate sheets can be used in:

Façades and curtain walls

Skylights and atriums

Roofing and canopies

Internal partitions and daylight panels

This design flexibility enables architects to achieve innovation points under LEED and integrated design credits under GRIHA.

Polycarbonate vs Glass in Green Building Design

| Parameter | Polycarbonate Sheets | Glass |

|---|---|---|

| Daylight Diffusion | Excellent | High glare |

| Thermal Insulation | Very High (multiwall) | Low unless double/triple glazed |

| Weight | Lightweight | Heavy |

| Impact Resistance | Extremely high | Fragile |

| Sustainability | Recyclable, low carbon | Energy-intensive manufacturing |

This makes polycarbonate a performance-driven alternative to glass in certified green buildings.

Applications That Earn Green Building Points

Polycarbonate sheets are commonly used in:

Commercial buildings

Airports & metro stations

Educational institutions

Healthcare facilities

Industrial buildings

Public infrastructure projects

Each application contributes to daylighting, energy savings, material efficiency, and occupant comfort—key pillars of LEED and GRIHA.

Conclusion: A Smart Material for Certified Green Buildings

Achieving LEED or GRIHA green building certification requires thoughtful material selection—and polycarbonate sheets check all the right boxes. From energy efficiency and daylight optimization to recyclability and durability, polycarbonate supports sustainable construction at both design and performance levels.

For architects, developers, and consultants aiming to future-proof their projects, polycarbonate is not just an alternative—it’s a strategic advantage in green building design.