In the world of modern construction, safety standards are evolving faster than ever. Materials are no longer judged solely on aesthetics or durability — they must also meet stringent fire safety regulations. Among transparent and translucent building materials, polycarbonate has long been valued for its strength, impact resistance, and design flexibility.

Today, advancements in fire-resistant polycarbonate technology are setting new benchmarks for safety and compliance without compromising on performance or visual appeal.

Understanding Fire-Resistant Polycarbonate

Polycarbonate, by nature, is a thermoplastic material that offers excellent toughness. However, when exposed to high heat or flame, standard polycarbonate can deform or ignite.

Fire-resistant (FR) polycarbonate is specifically engineered with flame-retardant additives and special manufacturing processes to slow down ignition, reduce flame spread, and produce lower smoke emissions.

Key Features of Fire-Resistant Polycarbonate:

Self-Extinguishing: Stops burning once the flame source is removed.

Low Smoke Emission: Minimises toxic fumes in case of fire.

Enhanced Heat Resistance: Maintains structural integrity longer under extreme temperatures.

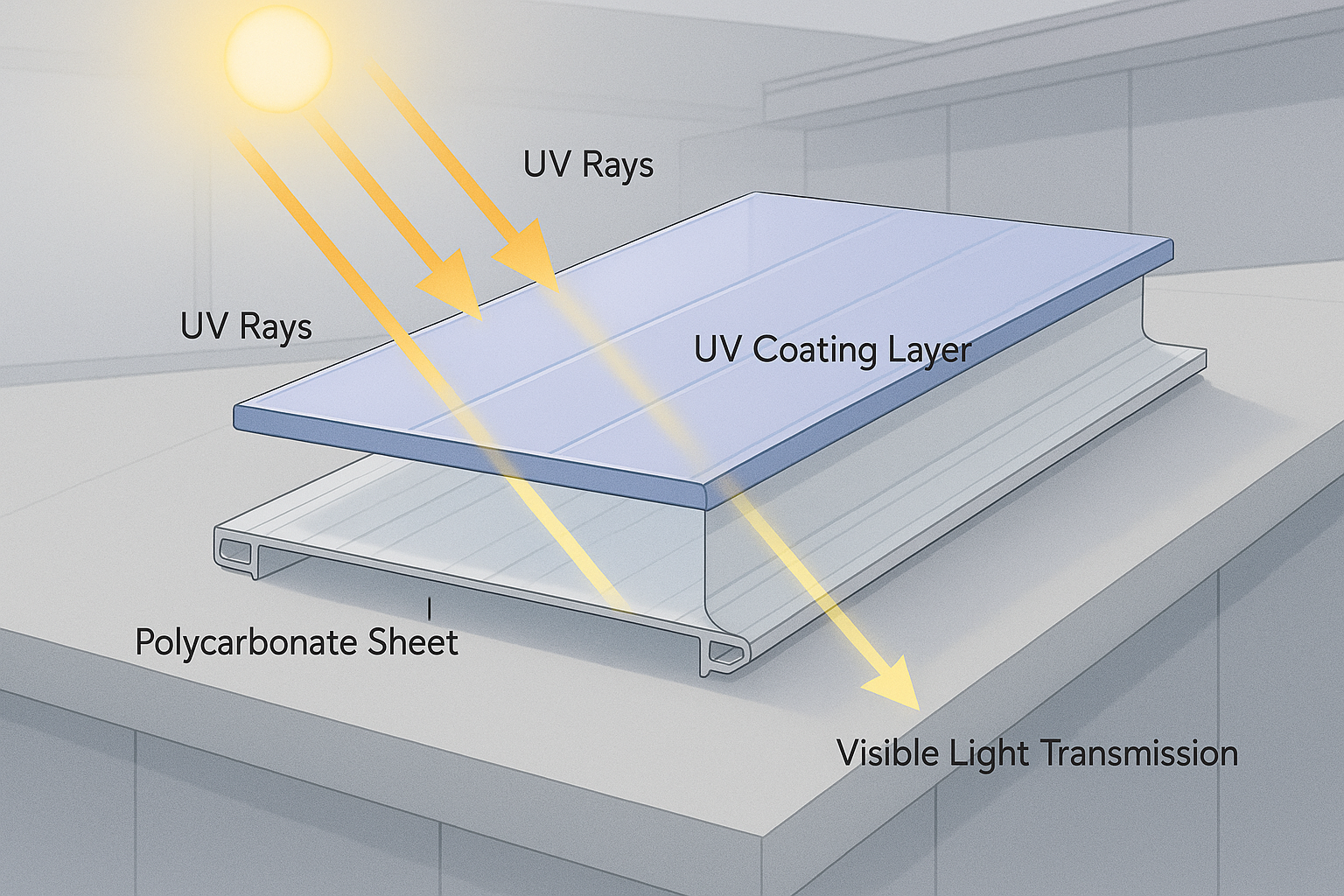

UV and Weather Resistance: Retains clarity and strength even in outdoor use.

Why Fire Resistance Matters in Polycarbonate Applications

With polycarbonate being widely used in canopies, skylights, facades, safety barriers, and interior partitions, fire safety is a critical concern.

In public spaces like airports, shopping malls, schools, and hospitals, building materials must pass national and international fire safety tests before approval.

Some common standards include:

UL 94 (Underwriters Laboratories) — Measures flammability of plastic materials.

EN 13501-1 — European classification for fire behaviour.

ASTM E84 — Standard test for surface burning characteristics.

BS 476 — British standard for fire propagation.

Recent Advancements in FR Polycarbonate Technology

1. Improved Flame-Retardant Formulations

Modern FR polycarbonate uses advanced halogen-free additives, making it safer for indoor use and environmentally friendly while still achieving excellent flame ratings.

2. Multi-Layer Co-Extrusion

Manufacturers are now producing polycarbonate sheets with special FR coatings on the outer layers, enhancing fire performance without affecting optical clarity.

3. Compliance-Driven Product Development

Leading brands now develop FR polycarbonate with specific regional compliance in mind, ensuring architects and builders can meet both local and international codes.

4. Lightweight Alternative to Glass & Metal

FR polycarbonate offers the same or better fire performance than certain laminated glass types while being up to 50% lighter, making it easier to install in large projects.

Applications of Fire-Resistant Polycarbonate

Commercial Facades & Skylights – Combining daylighting with safety.

Transportation Hubs – Airports, metro stations, and bus terminals.

Industrial Facilities – Warehouses, factories, and clean rooms.

Public Infrastructure – Stadiums, walkways, and covered public areas.

Safety Glazing – Protective barriers in public spaces.

Benefits for Architects and Builders

Code Compliance: Meets stringent fire safety standards.

Design Freedom: Available in clear, tinted, or opal finishes.

Durability: Withstands weathering, UV exposure, and impact.

Cost Efficiency: Long service life with minimal maintenance.

Sustainability: Many FR polycarbonate products are recyclable and halogen-free.

Conclusion

Fire-resistant polycarbonate is no longer just an optional upgrade — it’s becoming the standard choice for safety-conscious construction. With advancements in flame-retardant technology and compliance-focused manufacturing, FR polycarbonate offers the perfect blend of safety, performance, and aesthetics.

For architects, contractors, and developers, investing in FR polycarbonate means meeting today’s fire codes while future-proofing projects for tomorrow’s standards.